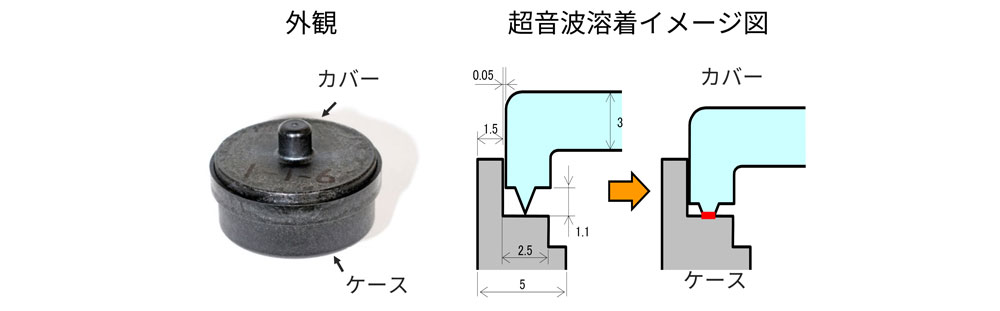

Elucidating bond state and strength formation mechanism

Mechanism of reduced weld strength between products with different shapes

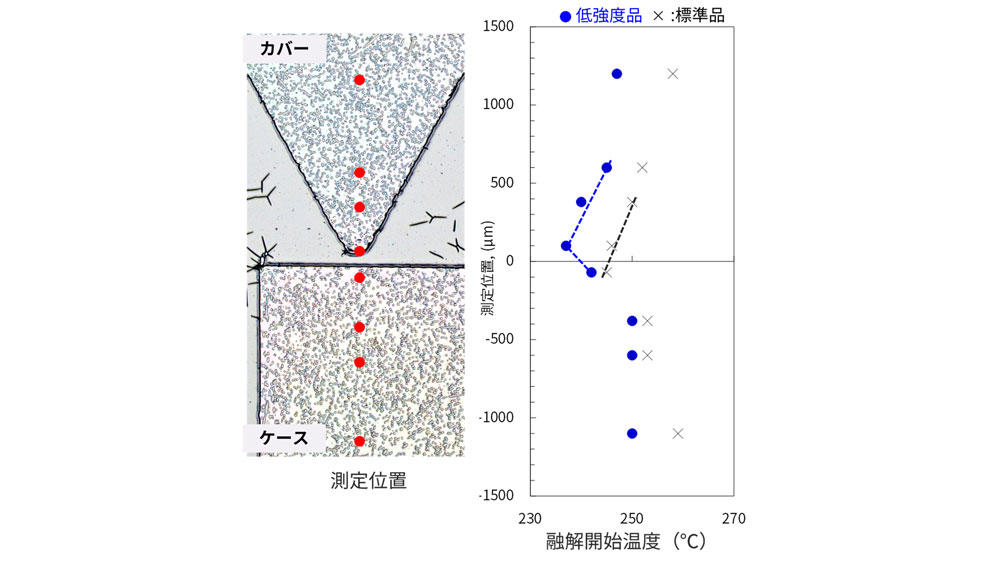

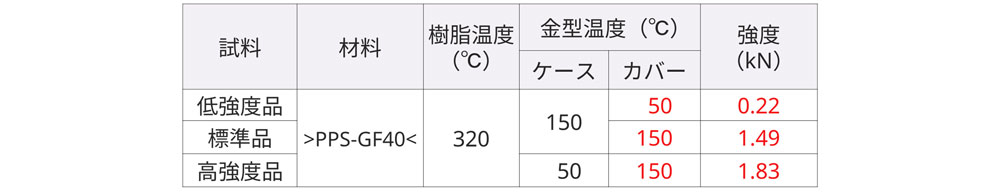

The higher-order structure of the joint, which determines strength, is determined by mold temperature and resin temperature, and is changed again by welding. To understand the mechanism of weld strength reduction, it is necessary to consider not only welding conditions but also molding conditions.

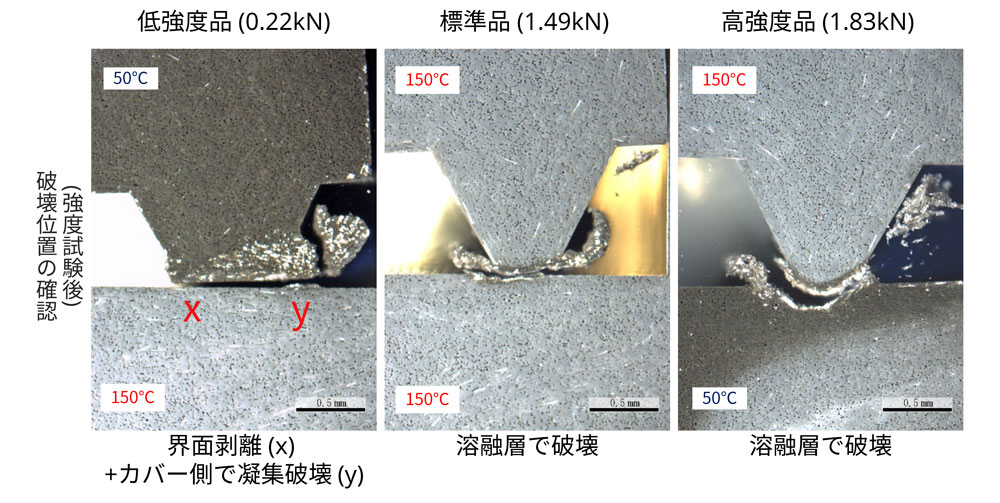

The cover of sample A, for which the mold temperature was set lower, had a lower melting start temperature of the material, so that only the resin on the cover side flowed during welding and was not compatible with the case, resulting in a lower weld strength.

In order to improve weld quality, it is desirable to bring the melting start temperatures of both welding parts closer together.